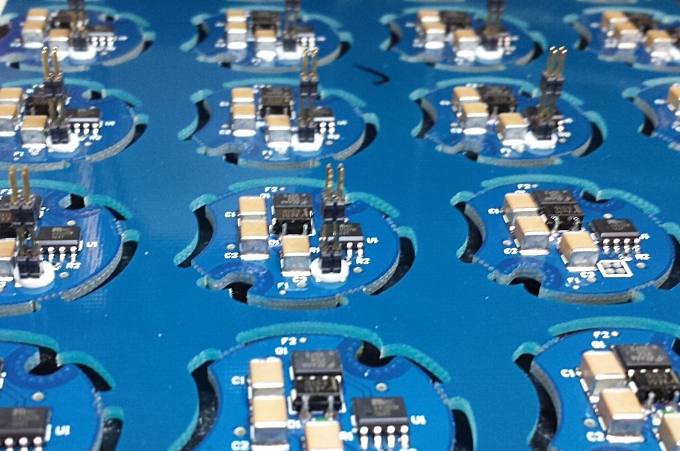

PCB Assembly

We work for you. As a privately owned service operation, we have the flexibility to tailor our capacity and make your job our top priority. We stand behind our agreements and work hard to insure our customers are completely satisfied. We will support engineering teams throughout the PCB population process of prototype & development, including builds that require ball grid arrays (BGA), thin quad flat packs (TQFP), plastic leaded chip carriers (PLCC), 0201 components and many others.

Service Default Our default application is as follows (a customer may customize any stage in this process):

Solder Paste: Tin/lead alloy: Sn63/Pb37 offers consistent dispensing results, and thus works well for our default process with minimal risk. A lead free version of this paste is also available to meet RoHS compliance.

Solder Wire: Tin/lead alloy: Sn63/Pb37 works well for custom fine-pitch applications.

No Clean Flux Paste: provides excellent wettability that is compatible with both conventional and lead-free solder to meet RoHS compliance.

Work Standard: Our team follows the IPC Class 2 standard for default builds, a customer may specify additional requirements upon this standard.

Pick and Place Builds: Capable of handling surface mount components as small as 0402.

Board Cleaning: Our quality standards extend to board cleaning prior to delivery. 99.9% isopropyl alcohol and/or environmentally safe de-ionized water will be utilized in conjunction with our ultrasonic cleaner for projects.

Component Capabilities

Our service offers an ideal mix of both mid-volume process and low-volume custom solutions. Our capabilities include Surface Mount Technology (SMT), Thru-hole, Single or Double Sided Placement, Fine Pitch Components, and much more. We can assist with quick re-work or more complex assembly tasks such as ball grid array (BGA), thin quad flat pack (TQFP), plastic leaded chip carrier (PLCC), different package types for quad flat no-leads (QFN), and 0201 components.

In our field, BGA services can be complex and expensive; however we have a low-cost BGA attachment process with a high yield success rate. Our experience affords a confidence that regardless the number of PCB boards, we guarantee a working BGA on every circuit board.

Framed Stainless-Steel Solder Stencils

Our stencil setup is clean, fast, and simple. Leveraging this tool maximizes the efficiency of solder paste application and minimizing cycle time. The universal frame holder accepts stencils up to 23" x 23" (584.2 x 584.2 mm). This process enables smooth printing for fine pitch applications.

Pick and Place Machine (PPM)

The PPM offers SMT placement for high precision SMT production and economic advantages. This modular assembler offers a comprehensive range of solutions for diverse SMT applications.

Service Customization:

OTSA is willing to review any application of cutting edge PCB components and sizes. Through custom hand assembly, we are capable of board assembly for surface mount components size 0201 and QFN / DFN package surface mount technology size .35mm

Prototype Boards: Rework is an inevitable part of prototyping, and we are here to help. PCB edits can be made directly at the customer site or at our location provided comprehensive customer instructions. A cost structure for this rework will be tailored to meet your needs.

This flexibility and quick-turnaround capability, allow us to provide rework assistance throughout the testing process. We can assist customers with on-board edits, modifications, cut/repair traces with copper tape, stacking components, tomb-stoning for pad and terminal exposure and reconnect, PCB fine-wire for makeshift on board connections and repair.

Given the nature of prototype development, we recommend a phased approach to board population. OTSA can provide an initial prototype batch to allow the customer to begin their own testing process. As necessary design changes are revealed, OTSA can respond quickly with subsequent prototype batches that incorporate any required design changes. Overall, this iterative approach provides a shorter cycle time to achieve a final design. Delivery service for these boards can be by courier for customers in the Central Texas area.